Today marks a significant milestone in the apparel industry of Sri Lanka.

With the arrival of technology, automated cutting rooms have revolutionized the way we approach garment manufacturing. These cutting edge solutions have not only enhanced efficiency and productivity but have also raised the bar in terms of precision and quality.

At Lectra and Apparel Technologies, we are deeply committed to ensuring that your valuable equipment operates at its optimal potential. Through regular monitoring of key performance indicators, we strive to uphold the highest standards of operational excellence.

In a landscape driven by demands for competitive pricing, reduced lead times, resource optimization & standards for precision and quality, it's time to Redefine Excellence. Join us on this quest to elevate the industry and set new standards of excellence.

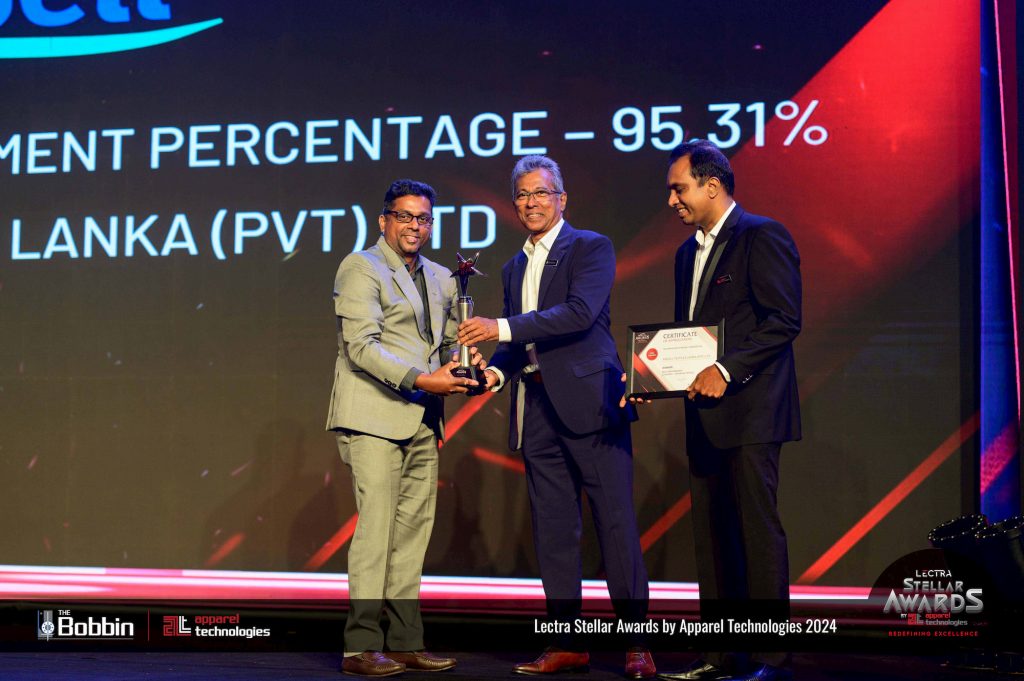

Lectra Stellar Awards by Apparel Technologies is all about honoring the trailblazers who redefine the game of apparel manufacturing.